Art thou mocking my turbo economy and TBO? Fie!

Hahahahaha! I think I’ve totally misjudged this contest and built the wrong engine  I was working to keep my power plant under a million dollars each. 10ish liter ohv v12 turbos with some fancy stuff on them.

I was working to keep my power plant under a million dollars each. 10ish liter ohv v12 turbos with some fancy stuff on them.

Never mind the Cadillac of airplanes, I’ve built the Maybach!

I tried a V12 but it was just too heavy for my taste!

I can’t remember for sure but I think my engines weighed like 560lbs each, but my economy was like half yours.

lol. that is… if your plane could fly at all for more than half an hour

edit:

bruh. 560lbs is not heavy… fuck me. 630lbs though a V engine might result in higher frontal area though

@Riso

well this will be interesting…

Hey riso… Why is your chart p units only 64 when the picture shows 456?.. because I messed up lol!

@mrchips I put performance units in place of production units on my excel file, could you fix that before grading my entry…

Looks like I misjudged the economy. ![]()

Again. ![]()

If I hadn’t gone three blades I could have carried eight people with a full fuel load!

This is a estimate as I don’t remember my actual production units, I think I found the right value in the lua file but I’m not sure.

I’m doing this on mobile as I’m no where near my computer.

I’m definitely in a different price class than you two and that probably is going to take me out if the running. But I’ve got a shorter takeoff roll, better climb, more TBO, and I think my engine economy was only 277.7 g/kwh @koolkei yeah when I said my economy was half riso’s I’d meant it only burned half the fuel

I already fixed it, don’t worry!

Thanks, $998k per engine was probably asking a bit too much.

##FROM THE COCKPIT - AAI Super Airmaster 200

For almost fifty years now, AAI has been at the top of the heap of the executive twin market with the Airmaster family. First taking flight in 1971, the Airmaster 100 quickly gained a reputation for being an efficient, durable and versatile workhorse, an aircraft just as comfortable in a corporate charter fleet as it is in the most remote, austere airports in the world. Seven years later, the larger, 12-seat Super Airmaster 120 joined the family, adding dramatically more capability to the family, with its 4900-pound useful load, 300-knot cruising speed and a range of nearly 1500 nautical miles. AAI built nearly five thousand Super Airmaster 120s in the ensuing forty years, becoming an aviation legend in the process. However, after forty years, AAI decided that it was time to improve the 120, with all-new power, a more luxurious and versatile cabin, and Rockwell Collins’s fantastic Pro Line Fusion integrated avionics suite in the cockpit. The resulting aircraft, now designated the Super Airmaster 200, improves dramatically over its predecessor in nearly every way.

##First Impressions

As we walked up to the second production Airmaster 200, N202SA, we were greeted with a familiar sight, but with a few subtle differences in the $3.85 million aircraft. First and foremost are the engine cowlings; for the Airmaster 200, AAI abandoned the previous gas turbine power and adpoted an all-new engine, the Avi Industries Avi8; more on this new engine later. A set of winglets and a smart, modern paint job completed the “familiar, but different” look of the new aircraft. pre-flight walkaround is largely the same as it is on the Airmaster 120; the only major differences are that there are two sightglasses per engine - one for engine oil, the other for the liquid coolant - that must be checked for fluid level, and the engine radiators (there are two; one for the engine itself, the other for the turbocharger intercooler) must be verified clear. After that, we boarded through the large rear entry door - the extra-wide cargo door/airstair combination is now standard fitment - and through the spacious cabin to the cockpit.

###Avi8 Power - Light, Efficient and Powerful

Preflight checks are simple and fast, and within ten minutes we had both engines running and the flight plan loaded into the Pro Line Fusion avionics. Operation of the Avi8 engines was simple - there is only one lever for each engine, with fuel condition and propeller RPM controlled by the dual-redundant Full-Authority Digital Engine Control (FADEC) for each engine. Start and test consisted of pressing the autostart switch for each engine, and once each engine was idling smoothly, flipping a switch to test each FADEC independently. The large, twin-turbocharged V8 took a few minutes to warm up to operating temperature, and adequate warnings on the engine pages warned against using excessive power before the engines and gearboxes warmed up sufficiently. FADEC controlled cowl flaps kept engine temperatures in check the whole time on the ground, and an optional electric cooling fan can be fitted for operations in hot environments.

With AAI’s chief pilot and myself aboard, along with 2600 pounds of fuel - good for just over four hours of flight time - 2SA clocked in at 10,521 pounds, almost a full ton below the maximum takeoff weight of 12,500 pounds. After we got taxi clearance, we made our way to the active runway, where after a short delay we proceeded with the takeoff. The Avi8s responded quickly to power changes, building boost rapidly as the engines ran up to their full 6000 RPM redline, producing a combined 1550 horsepower. Noise levels have improved over the Airmaster 120 thanks to new 94-inch diameter propellers, and the soundtrack provided by the V8 engines would be familiar to anyone who owned a muscle car in the 1960s and 70s. The takeoff was fast, taking just 1500 feet of roll, and the aircraft settled into a rapid climb of about 2200 feet per minute; even at maximum weight, the aircraft can still exceed 2000 fpm on takeoff easily.

Climbing rapdily up to 31,000 feet, we levelled off to test out the cruising capabilities of the Airmaster 200. 75% power showed 315 knots true, essentially right on the company’s promise of 316 knots. Pulling the power back further and we saw 290 knots at 55% power, just shy of the 292 knots in the manual, but that speed is achieved at the service ceiling of 35,000 feet, which we were unable to attain on the day due to air traffic restrictions. Regardless, this represents a substantial improvement over the Airmaster 120, which on a good day could only reach the mid-290s at 75% power. This is made possible by the Avi8’s incredible ability to produce their full 775 shaft horsepower rating at all altitudes on a standard day, a trait that only one other candidate engine was capable of during the selection process.

Satisfied with that performance, we failed an engine to test the Airmaster 200’s engine out handling. As expected, engine-out handling and performance was stellar, with the aircraft able to maintain just under 30,000 feet on one engine; again, a truly remarkable performance far ahead of any of their rivals. After a rapid, single engine descent, we levelled the aircraft at 7,000 feet and preformed a simulated engine-out approach. At 5,000 feet, we initiated a simulated missed approach and went to maximum power on the good engine, seeing a respectable 300 feet per minute climb rate; more than enough to satisfy the regulatory body.

###Final Thoughts

Starting the other engine, we brought the aircraft back to the field and shot a routine approach, the Pro Line Fusion avionics making the approach a cinch, with a wealth of useful information right there for the crew to see. As we taxiied back to the AAI flight test ramp, I reflected on the forty years of progress on display today, truly, the future is bright for AAI and the Airmaster family. New power, avionics and cabin have given this workhorse a new lease on life, moving the goalposts in this category for likely another forty years.

##Overall Results

##Individual Results

####Seventh Place - Leonardo9613

While this was by far the smallest (and by extension most aerodynamic) engine of the group, it was held back by a few things - the turbocharger was very small, and was already maxxed out producing power at sea level, and the small propeller hampered efficiency considerably; at this diameter, a five or a six-blade propeller would have been more approprate for this power level. Fuel consumption was an issue as well, as evidenced by the range of the aircraft - this was also not helped by the inability to produce rated power beyond about 9-10,000 feet, which was the lowest of any entry. In this challenge, it was critical to get as much power as you possibly can at high altitude, because this gives a huge boost to cruise speed and range all by itself. Very, very good payload though!

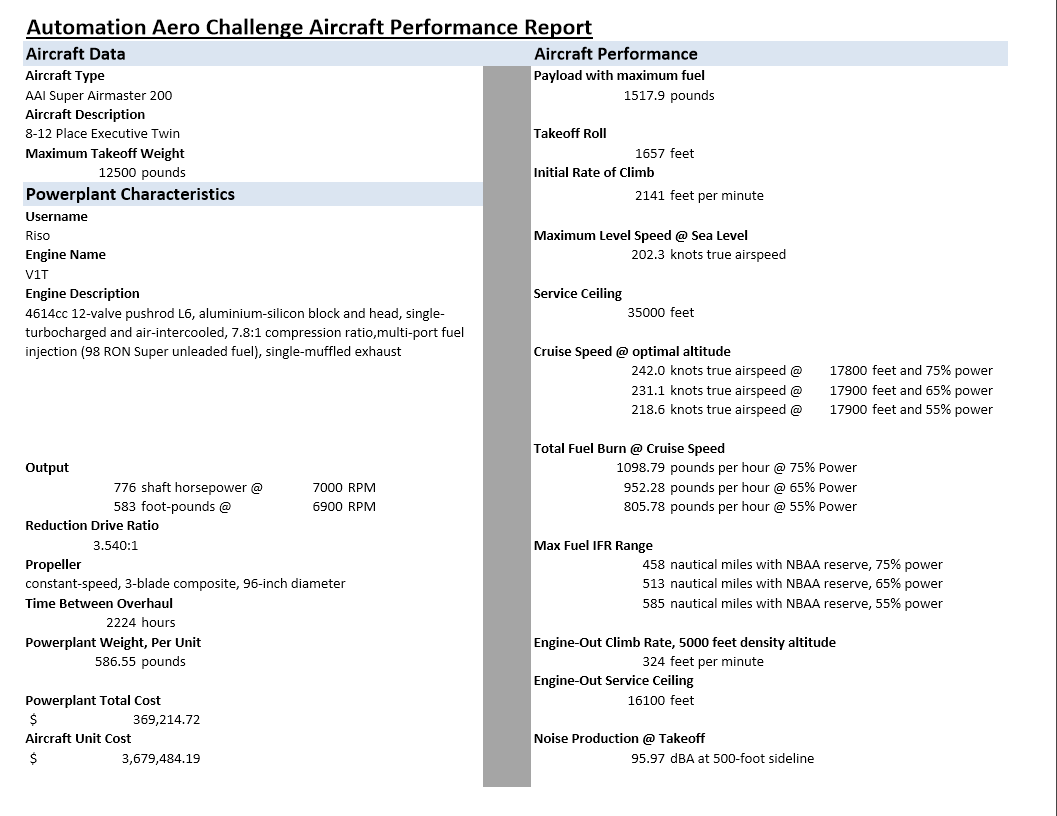

####Sixth Place - Riso

Another very lightweight engine, but this one is even cheaper. However, it too sacrifices a lot of performance and reliability to save money; this was the only engine to not use direct fuel injection, for one. Also, the specific fuel consumption of this engine made it suffer tremendously in terms of range, but at the same time the propeller, while cheaper and simpler than most, was very well matched to the engine and made up for quite a few deficiencies otherwise. Not the best propeller in the challenge, but good enough.

####Fifth Place - koolkei

This engine puzzled me, frankly; it was cheap, reasonably reliable and good-performing in a few categories, but it got absolutely trounced due to turbocharger design - again, it did not have the ability to produce enough boost to keep the power up beyond the teens. As a result, it is a relatively low-altitude cruiser, which hurts cruise speed substantially, even if the specific fuel consumption is low enough that it can more or less compensate in terms of range. A good propeller, essentially the same four-blade, 96-inch metal constant speed unit that everyone else arrived at, was probably the best overall combination of cost, speed and weight.

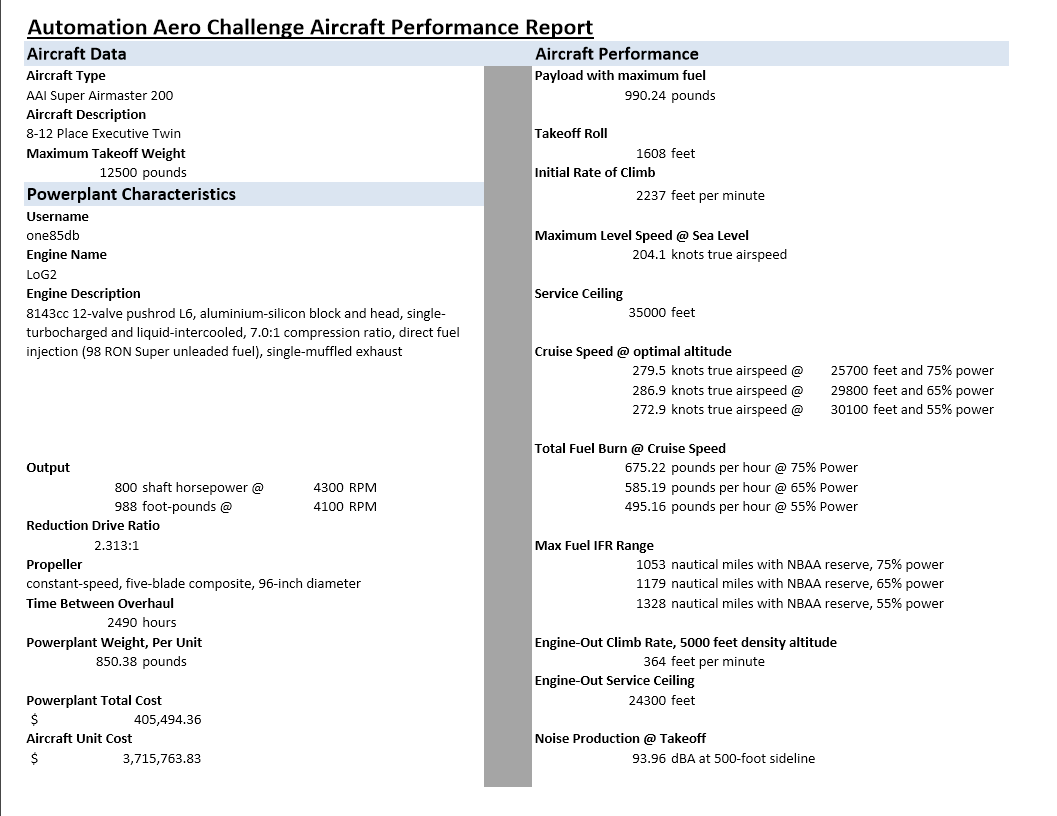

####Fourth Place - one85db

Once I lopped off a few inches of propeller to give the aircraft, you know, ground clearance, this entry performed rather well actually. Apart from a turbo that was a bit too small, and a specific fuel consumption that ate a little too much into the range of the aircraft, this was a reasonably competent entry regardless. The relatively slow-turning 5-blade propeller was by far and away the quietest propeller in the field, and gave the aircraft very impressive climb performance indeed.

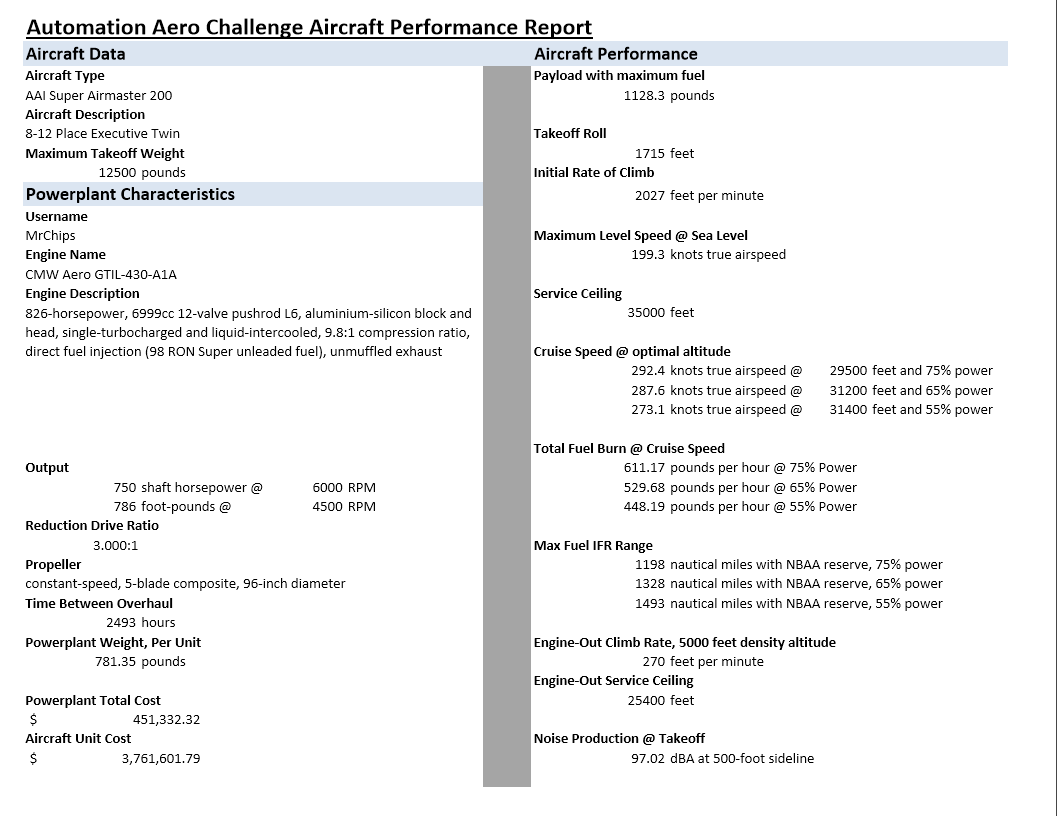

####Third Place - MrChips

My engine was, looking back on it, a bit too far in the direction of size over efficiency - a bit more displacement would have helped a lot there! I also didn’t work the propeller smart enough either - I left a lot of performance on the table as a result. That said, that oversized turbocharger paid off in spades…almost!

####Second Place - nialloftara

Tremendous performance, excellent speed, excellent range…just, way too expensive! I was actually pretty surprised to see a V12 so competitve in terms of weight and aerodynamics in this challenge - I thought inline-6s would rule the roost, quite wrongly in fact, as the top two engines are both vee-configuration. My guess is some of that is down to two smaller turbos rather than one big one, but even still, a surprising result regardless. Once again, nialloftara arrived at what appears to be the best possible propeller design, combining efficiency and performance with low(ish) noise. Well done!

####First Place - LaffingHyena

Once again, we find ourselves with an engine that isn’t the best in every category necessarily, but put up some numbers in some categories that were simply untouchable. This engine’s ability to produce full power over the full range of altitudes was key to, well, everything, climbing faster and harder than any other aircraft, and was able to get up to the highest altitudes to produce the highest cruise speeds. Additionally, the reliability was far beyond anything anyone else was able to manage - I can only imagine what this engine would have been like if it was paired with a more optimised propeller. As it is already, it’s the only powerplant combination that largely matched the performance of the real-world model aircraft, so well done!

Holy shit, that didn’t go well!

My excuses: I have past experience in the university aero design team, and I was the one responsible for the engine, power and making sure the plane could take off. Choosing a propeller typewas very straight forward for me, but I wanted to go for a larger propeller, but the numbers kept staying on the red if I did so, especially the noise one, something about spinning too fast, which I had to, since the engine was so small, Back then, our main issue was in generating enough lift to push the plane up, fighting against the drag, therefore every single gram of weight had to be taken out. That’s why I decided to go for a very light and small engine.

Nowadays, I work at cost cutting for a major car company, therefore it is ingrained in my head that it should be as cheap as it could be.

And I pretty much forgot all the rest of the criteria

EDIT: I need to redeem myself in round 5. Please let it happen soon

Ahh so close even with the maybach pricing. Nice job @laffinghyena great reliability and range. @MrChips as always thanks for a great challenge round.

I won a thing!

Does this mean I have to stop making jokes about my designs being perils of the airways?

I am not last. Woo!

Thanks Leo.

Another round please?

I’m really busy with work stuff these days, but another round will likely arrive sometime around the end of the month, all things being equal.

Great, will be waiting (im)patiently for that!