Hype

heyheyhey

that’s my role in this forum to do that.

##HYPEHYPEHYPEHYPEHYPEHYPE

Don’t.

Don’t.

Don’t believe the hype.

twitchy waiting

Sorry for the delay, guys…I’ve been up to my ass in alligators lately. Anyhow, here’s what we have!

#FOR IMMEDIATE RELEASE

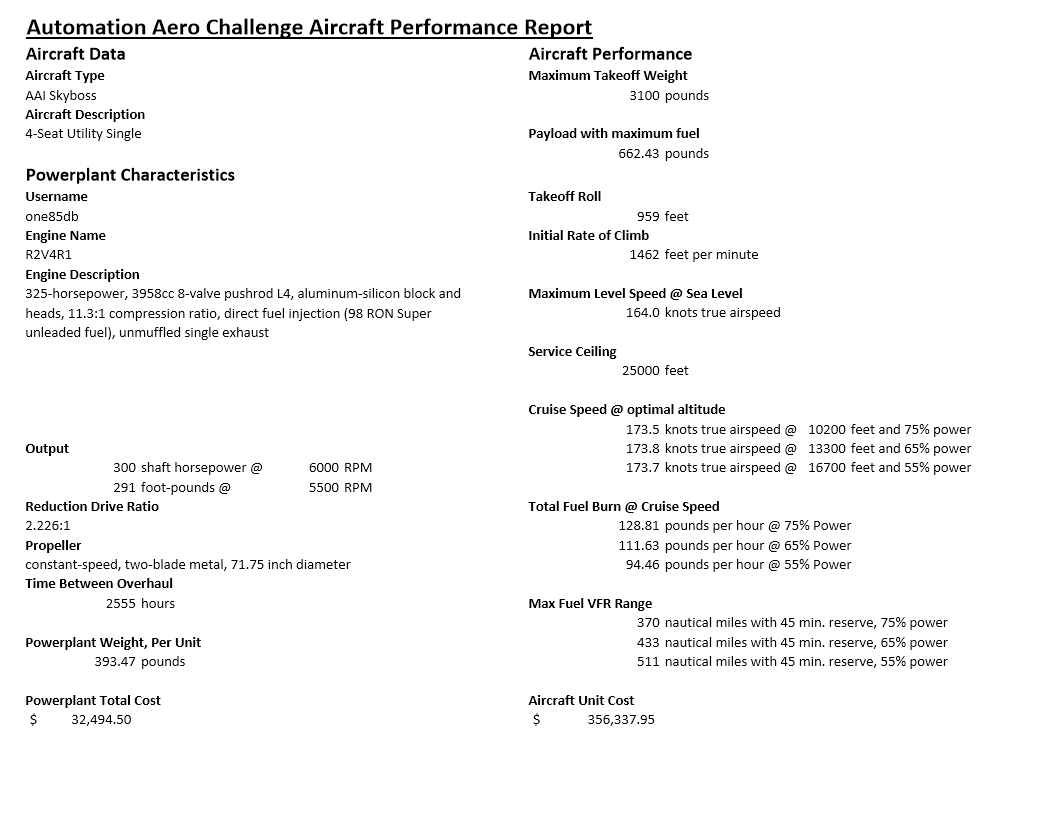

##AAI Chooses CMW Aero and Aero8 to Power All-New Skyboss Single

After an extensive evaluation of available powerplant combinations suitable for their new Skyboss four-seat single, Automation Aviation Industries (AAI) has selected the VL-450 from parent company CMW Aero, and in an unusual move, also chose the Aero8-470 as an alternate powerplant.

“Our engineering team spent countless hours pouring over the details of each powerplant combination as provided to us,” says CEO Chips McCloud, “but in the end we felt that the VL-450 offered the best combination of performance, reliability and economy on the market today. Additionally, the Aero8-470 provides a much simpler powerplant and far more durable option as well, though no less suitable than the CMW Aero offering.”

The CMW Aero VL-450 is the latest offering from CMW Aerospace, the parent company of AAI. The all-aluminum, 7406cc pushrod V6 is of CMW Aero’s new modular engine family, and utlises a direct-drive arrangement to drive the propeller, in marked contrast with many of the offerings on the market today, saving the weight and complexity of a reduction gearbox. Additionally, the pushrod V6 layout makes for simple packaging and, most importantly in today’s aviation market, very low operating costs. In the Skyboss, the VL-450 will be flat-rated to 250 horsepower, coupled to a 76-inch, two-bladed, constant-speed propeller of composite construction.

The Aero8-470 is a tried and proven pushrod V8 engine, displacing 7615cc and producing 200 horsepower in the Skyboss. Coupled to a simple, fixed-pitch wood propeller, driven directly from the crankshaft as in the VL-450, the Aero8-470 offers class-leading TBO and fuel economy, burning 8.2 US gallons of fuel per hour at cruise in this application, according to AAI performance specs. Simple systems and common materials help keep the cost of the Aero8-470 low, and contribute to the durability of the motor. As such, it is being offered on versions of the Skyboss being sold in export markets, and to operators and pilots who will be operating the aircraft in remote, austere locations.

The AAI Skyboss light single will be on sale starting December 2016, starting at $366,775 for the Skyboss-200 and $379,025 for the Skyboss-250.

##Evaluation and Results

And yes, before you shout about it - I do know that the Powerplant Calculator didn’t really help out in some ways this round - next round, it’s going to be completely different. In fact, going forward, the only way to make this thing function properly is to have a unique calculator for each round - that way, it can give you some concrete information to go upon.

Detailed evaluations will follow tomorrow or Friday

Considering the displacement disadvantage i kinda set myself into, i was quiet competitive in some of the categories.

I can’t believe my fuel burn was that bad, and that result was with it being as lean as possible @ 15:1.

i’d suspect that your cam profile are higher than 20?

Hot damn! Second place and not far off first, wish I understood the climb and takeoff physics a bit better that seemed to be my downfall.

Yes, it was, I was trying to get the best fuel mileage I could @ high RPM not in the middle RPM range. I was under the impression that with a constant speed prop the engine was turning at a constant speed, most likely at it’s most efficient point and the prop changed its angle to determine speed.

I suppose that would be a little undesirable as the prop would not always be able to absorb the 300 HP the engine would be pushing at its most economical point.

OK, time for a detailed breakdown and some feedback on this round!

But first, some important news; I have received word from the Gasmea Aviation Authority that in the face of growing environmental concerns, all new-production aircraft certified for use in Gasmea will be evaluated for their effect on noise pollution in and around the country’s numerous airports. An exposé in one of the country’s leading newspapers lambasted the aviation industry, and in particular AAI, for their utter lack of concern about aircraft noise levels. In clandestine testing, it was found that the upcoming Skyboss-250 produced a peak of 98.6 decibels at a 500-foot sideline - a level roughly equivalent to a high-performance race car at that distance. Additionally, when asked about the cabin noise levels in AAI’s new aircraft, owners and pilots replied only with “WHAT?!”

Anyways, on to the feedback…

@8bs Your powerplant was perhaps a bit too small to be really effective in this challenge, less from a power perspective and more from specific output perspective. This meant your cam setting was a bit on the high side, which hurt your fuel economy some. Also, your propeller choice was good in some ways but not so good in others. The three blades added weight and cost, but the relatively slow propeller speed, combined with a smallish diameter, kind of offset the benefit here - climb and cruise efficiency suffered some. This challenge was about at the point where you could easily justify either a two or a three blade propeller, so it was interesting to see the choices everyone made.

Interestingly, your engine had the smallest frontal area of all; this isn’t important just yet, but when we get into multi-engine challenges, this will be a big deal!

@AirJordan Your powerplant was fairly light weight and powerful - you were at the higher end of the recommended power level. As such, your performance was good in a lot of ways, but that much power does come at a price - increased fuel burn and decreased range. The small propeller you chose was your Achilles heel - the small size meant your efficiency suffered, so a lot of that power was simply frittered away. A longer, slower turning prop likely would have put you quite a bit higher in the results.

@Kilonum your powerplant submission was dramatically improved from the first round - you burned the same amount of fuel per hour as that engine, but got triple the power output! However, like above, lots of power comes with the price of increased fuel burn and decreased range. You were also helped out by your propeller choice; that big, three-blade prop was by far the most efficient of all in this challenge and it helped you out pretty dramatically.

However, your engine was hideously complicated and quite a bit too heavy…really, it was massive overkill in a lot of ways. Perhaps those titanium con-rods were slightly inappropriate, considering the other engines used forged steel or even cast parts. This would have been a HUGE cost savings just by itself.

@koolkei Your powerplant was very lightweight - at the expense of cost, one could say, but that size meant you had to work the engine harder to make what you wanted, and as such your specific fuel consumption was a bit higher than average. Otherwise, your performance was decent all around…just, not enough to push past sort of average values.

@MrChips My engine was too heavy, plain and simple; the payload was the absolute bare minimum; with three 195-pound passengers in the seats and full fuel, that left a whopping 37 pounds for baggage…and that’s even after a very expensive weight reduction program. If anyone is interested, the first variation of this engine weighed almost 30 pounds more than this one, and, having just checked the initial version, that weight savings cost almost $14,000 to achieve. Other than that, I think it turned out alright.

@one85db Your engine was by far the most powerful, both before and after flat-rating. Combined with a moderately good propeller, your aircraft had phenomenal performance - you were the only entry to hit the maximum permitted altitude of 25,000 feet - but it was at the expense of huge fuel burn. Compared to the winning entry, your SFC was considerably higher (almost a full third higher in fact) combined with the fact that your propeller was less efficient and the simple fact you made a lot more horsepower for more of the flight envelope than anyone else did. This all added up to seriously curtail your range figures. Other than that, you have successfully retained your crown for the fastest aircraft of the round!

@nialloftara If this was just an evaluation of engines alone, you would have won this round, hands down. But, since propellers are just as important as the engines themselves, it cost you the victory. While a small, fixed-pitch wood propeller was cheap and light, it cost you dearly in every performance aspect. This was saved somewhat by your generous flat-rating, but your variant just could not keep up with the other aircraft in any way other than fuel burn and range. Now if I was more generous when I designed this challenge, I would have allowed your entry to have smaller fuel tanks to match everyone else’s range, thus trading fuel for payload, or for a lower takeoff weight. But I did not…perhaps that might come in a subsequent version of this challenge…

@Pzike In spite of being down on power, your engine worked quite well here in a lot of ways. While your takeoff, climb and altitude performance was not great, your efficient engine and low horsepower helped achieve a very respectful range and fuel burn. A longer, slower-turning propeller would have helped boost that, at the expense of a little weight and cost (which you had to spare). Good TBO as well too…overall, this was an encouraging first effort!

@Riso Your engine had very good fuel burn and range, but it’s high weight, low power and small propeller really made it suffer in altitude and cruise performance. Your cost and TBO were also excellent, but I get the feeling you might have cut a bit too much performance to save cost in this case. Even 20 more horsepower would have made a huge difference here! Heck, even 20 horsepower behind a similar flat-rate of 180 horsepower would have helped a lot too!

So, that concludes this round…Round Three will be coming soon, once I get things straightened out with the new Powerplant Calculator, and a few sort of messy calculations in the model I need to clean up. I need your input, though…would you rather see a challenge that introduces multi-engine aircraft, or turbocharging? Both will have a separate challenge to introduce that complexity; this is just to see which you’d like to see first!

- Turbocharging

- Multi-engine Aircraft

- Maybe neither (another challenge to sort things out before we bump the complexity)?

0 voters

So a larger slower propeller reduces fuel consumption too?

Both directly and indirectly. A larger propeller has a higher efficiency value and (often) more static thrust, meaning you can climb to altitude faster and convert more of your engine power into thrust, which makes you go faster for the same power. There are a lot of factors at play here, but the difference between a minimum size prop and a maximum size prop in this past challenge was something like ten to fifteen percent when all the factors were addressed.

seen as you seem to be tweaking the calculator and working out the next challenge, Can i suggest a “interim round”

Obviously this would be best with the previous rounds winner, But a “tweak and refine round” of the the last winners engine/prop in the same aircraft.

Nice feedback! Slowly is my understanding getting there  Looking forward for next round

Looking forward for next round

I’m still really busy for the next week or two, so I think we’ll just have to wait until the next round of the challenge.

Speaking of which, the next challenge will involve multi-engine aircraft, as you have all requested! To make things more interesting, it will also be a single- versus multi-engine challenge, the size of the aircraft to be determined as yet. This means I will need to add on some engine-out performance calculations to my simulation model, but this shouldn’t be overly difficult considering I already have a working set of equations for this very purpose.

In the coming days, I will make a more detailed post going into the benefits, drawbacks and other important things to know about how this will work.

##Multi-Engine Challenge Guide

If you’ve ever looked up at the sky and seen an aircraft fly over, you’ve probably noticed that apart from the very smallest aircraft in the skies, a large number of designs use more than one engine. There are, of course, a number of advantages and disadvantages to a multi-engine aircraft, and a lot of design compromises that result from this.

###Redunancy and Reliability

The ability to continue flight if an engine fails is one of the most important reasons why aircraft sprouted a second engine not long after the Wright Brothers flew for the first time. Just as important, it allowed for a dramatic improvement in safety considering the rather suspect reliability of the engines of the day. In fact, it has only been in the last 25 years or so that aircraft engines were reliable enough that single-engine aircraft would be afforded the same privileges as a multi-engine aircraft in commercial operations.

As such, the next challenge will include, in addition to Time Between Overhaul (TBO) calculations, a Mean Time Between Failure (MTBF) calculation. There will be no points scored on this number, but for certain aircraft, there will be a minimum acceptable value if you opt for a single-engine design - powerplants that do not meet this criteria will be disqualified. The calculation will be in the latest Powerplant Calculator, but the MTBF calculation will be as such:

e^((Reliability x 100)/Rated Horsepower (flat-rated or maximum))

The minimum value will be 100,000 - matching the generally accepted value of one engine failure per 100,000 flying hours for commercial IFR operations in a single-engine aircraft. As an example, a 500-horsepower engine would need to have a minimum reliability of 57.6 to meet this criteria. This shouldn’t be tremendously difficult to achieve with 2016 technology levels, but it will become difficult, if not impossible, when or if we do a challenge in earlier years.

###Cost

In this challenge, powerplants become considerably heavier and more expensive the larger and more powerful they become. For each challenge, there may be a point where the increased airframe cost, weight and drag is offset by the ability to use two or more cheaper, lighter engines than one large, expensive and heavy engine…even more so if the minimum MTBF is in play.

Speaking of cost, multi-engine aircraft will pay more than just a potential cost penalty in this challenge. As discussed in the original post, single-engine aircraft have no drag penalty associated with their ppwerplant other than that of the cooling system. In a multi-engine aircraft, there is a drag penalty from each engine nacelle in addition to the cooling system penalty, the calculations for which are detailed in the first post yet again. This means that engines with small frontal areas will produce less drag than an engine with a large frontal area. So, a comparably-sized inline-6 will perform better in this respect than a V6, which will tend to have the worst frontal area (and length, which affects the fineness ratio of the engine nacelle) for a given engine size. Also, a V8 will do better than a comparably-sized V6 because the engine will be physically smaller (due to the smaller bore/stroke needed for a given displacement) than the V6. Other things will affect engine frontal area as well, such as the type of intake and exhaust selected and the valvetrain layout. Additionally, multi-engine aircraft require larger vertical stabilisers and rudders to counteract asymmetric thrust in the event of an engine failure, which also comes with a slight drag penalty.

###Engine-Out Performance

This is one of the biggest issues with a multi-engine aircraft; how it performs with one engine not functioning. Unfortunately, it isn’t as simple as “two engines, lose one… 50 percent of maximum performance”. The reality is that because the aircraft wants to yaw and roll into the inoperative engine, you need to use a coordinated application of rudder and aileron to hold a small, continuous bank angle into the good engine, as well as holding an input to the rudder.

This produces a fair bit of drag by itself, in addition to the drag associated with the propeller of the inoperative engine. The net result is that the loss of performance is far higher than just 50%…the rough rule of thumb is that you lose 85-90% of your climb and altitude performance with one engine inoperative in a twin engine aircraft (this proportion drops in aircraft with more than two engines, and changes based on which engine fails in those cases, but generally the worst-case scenario is assumed in any performance calculations). So all of a sudden that twin that climbs at 2000 feet per minute with all engines running is now wallowing along at 200-250 feet per minute with an engine out.

There are certification requirements for climb gradient with an engine inoperative in reality, and they will apply in this challenge as well. They are much more complicated in reality than what we will use, but how the challenge calculates performance means I only need to factor the worst case scenario for each group. This will all be worked into the calculator when it comes out, so you don’t need to know numbers off by heart, but here they are for those who are interested:

Normal Category, <6000 pounds gross weight, stall speed <61 knots:

No climb gradient necessary

Normal Category, <6000 pounds gross weight, stall speed ≥61 knots:

1.5% (91 feet per nautical mile)

Normal Category, ≥6000 pounds gross weight:

0.75% (46 feet per nautical mile)

Transport Category:

Two-engine - 2.4% (146 feet per nautical mile)

Three-engine - 2.7% (164 feet per nautical mile)

Four-engine - 3.0% (182 feet per nautical mile)

Normal and Transport categories are certification categories for aircraft; they will be specified in the design criteria of each challenge going forward.

This climb gradient calculation will be used as a scoring category, as will something known as the “drift-down altitude”, which is the maximum altitude an aircraft can maintain with one engine inoperative and the remaining engine(s) at maximum continuous power (which for the sake of simplicity in this challenge is just maximum or maximum rated power). Since single-engine aircraft have no engine-out climb gradient or drift-down altitude, aircraft will be scored as a percentage of the maximum possible points in single versus multi-engine challenges, rather than as a plain raw point value as we have seen in both rounds so far.

On another note, I am taking steps to build in stability calculations, with the engine weight and position having an effect on the aircraft’s handling characteristics…essentially, I am closing in on actually designing and building not just a functional aircraft simulation model, but simulated aircraft as well! It isn’t hard to imagine the next step as throwing something together for Microsoft Flight Simulator or X-Plane and actually flying our creations “for real”!

And now I’m daydreaming of using this as a stepping stone to Aeronation: The Airplane Company Tycoon Game!

Goddamn… 1500 hours of war thunder doesnt seem to help as much as i thought.

A few question then. Is climb gradient and climb rate contextually the same thing?

Also, is there a minimal power to weight and/power to drag ratio to keep a multi engined aircraft to keep flying? Or at least maintain it’s altitude. Because some multi engined plane cant even maintain it’s altitude and only manages an extended glide even with the WEP/NOS/110% power on the game

Keep in mind that a lot of war-planes aren’t exactly the most stable aircraft in the world to begin with. Multi-engine aircraft typically were used as bombers, and that the payload was often times maxed out to what the aircraft could carry with 100% power. Why do you think it was common for a damaged bomber to drop their bombs early if they had an engine going out? Because if they didn’t, they’d carry that all the way to the ground.

Passenger/cargo aircraft today have to maintain a lot better flying characteristics because you can’t just dump the cargo if you lose an engine. They have to make it to an airfield.