Maybe it’s too early to speak about this ‒ it is something that is going to be useful once the tycoon mode it’s completed ‒ but it growth so much in my head that I have to lay down some ideas and have feedback about it.

Let’s talk about derivative engines.

[size=120]PROLOGUE[/size]

I don’t know if “derivative” this is the right technical term, what I mean is when you build a new engine not from scratch but from a previous existing engine, re-using the block and several other components in order to reducing time and money involved in the design/engineering/prototyping process. (D/E/P from now on)

For example: building a 1.7 liter EFI engine from an existing 1.5 liter carburettors one.

I’m expecting that building a new engine from scratch it take a lot of time and money (probably depending from the “era” or the components? [carburettors are cheaper to implement than a DI system]) and this feature will give a hand to the player that plan a long term strategy and also have a correct side effect to balance it properly.

If building a new engine from scratch it will not have any D/E/P cost all this discussion it’s useless.

[size=120]IN GAME LOGIC[/size]

Let’s assume that in career mode we have a engine manager UI similar to the actual platforms/models system.

You can develop a new engine from scratch and this is going to be defined as “Native” engine.

To make a derivative engine from it, you choose the native engine and click on the “New derivative”.

Scrap an engine or a derivative if you are not going to use them anymore (maybe this option could put the engine and the cars in a some kind of archive/museum area… I like the idea

)

)I’m not sure about the revision. Probably to mess a bit with the engine and look how you have made it. Do not give an option to look the engine parameter inside the editor seems not right to me.

Now… let’s take a look at the engine components in the game and how their design affect other components.

BOTTOM END

Let’s skip for now the engine block option.

–Block Material

Changing the block material mean re-calculate all the block dimension due the material propriety differences (thermal expansion, hardness, fragility etc.)

Cost modification: Very High (I’m wondering if the possibility to apply of modification possible it’s pointless or not)

–Bore

Changing the bore size in real life is possible. That means to develop new pistons and new head. From the native engine I will imagine a small range of modification of the bore… let’s say +2/-5mm maximum.

Cost modification: High

Bonus: No additional cost to change pistons/compression (included in the Bore size modification). Reduced cost of head redesign (changing the size is cheaper than design a whole new DOCH system from a OHV)

–Stroke

A cheaper alternative to vary your engine size. You must redesign the crank, but I’m not sure about the conrods. There is not a limit to the stroke variation, expect for the one already implemented in the game.

Cost modification: Low

Bonus: No additional cost to change the crank type (included in the Stroke size modification).

–Crank

Obviously you can change it, just tell me why? I hope you are going to put a huge turbo

Cost modification: Very low

Bonus: Discount for stroke modification.

–Conrods

You can change it. Are you going to pump up the rev limiter don’t you?

Cost: Very low

–Pistons

It seems logic that redesigning the pistons grant you also to change the compression.

Cost modification: Low

Bonus: No additional cost to change compression (included in the Piston redesigning)

TOP END

–Head and Valves

Changing the head it’s a costly D/E/P operation. Swapping between head type (OHV – OHC – SOHC – DOHC) means changing a lot inside the egine (for the OHV the block should change too!), for SOCH and DOCH valve quanity it’s little bit cheaper.

Cost modification (head only): Medium-High

Bonus (head only): No additional cost for leaded-to-unleaded modification (included in the Head redesign). Small cost discount from OHV to OHC because no camshaft modification required. (don’t know if too difficult to implement). Free (or very big discount) head material modification. Discount on VVT implementation costs.

Cost modification (valve numbers only): Medium

Bonus (valve numbers only): No additional cost for leaded-to-unleaded modification (included in the Valve redesign, valve seat in this case). No additional cost for cam profile modification (included in the Valve redesign, different number of valve need different designed camshaft). Discount on VVT implementation costs.

Cost modification (all): High

Bonus (all): No additional cost for leaded-to-unleaded modification (included in the Head redesign). No additional cost for cam profile modification (included in the Valve redesign, different number of valve). Discount on VVT and VVL implementation costs. Free (or very big discount) head material modification.

–Head Material

As for the engine block material, the engineers must re-calculate all the head dimension due the material propriety differences (thermal expansion, hardness, fragility etc.)

Cost modification: Medium

Bonus: No additional cost for leaded-to-unleaded modification (included in the Head redesign). Small price reduction for the head modification.

–Compression

A piston modification. So…

Cost modification: Low

Bonus: No additional cost to change piston type (included in the Piston redesigning)

–Cam Profile

Squeeze the power from that engine!

Cost modification: Low

Bonus: Discount on VVT implementation costs.

–VVT

There are some study behind it and mechanical stuff to fit in the camshaft timing.

Cost modification: Low-Medium

Bonus: Discount on cam profile modification. Small price reduction in head redesign.

–VVL

It’s a mess of additional camshaft and technology wizardry. The implementation of this system on an outdated engine head could be costly.

Cost: Medium (Medium-High?)

Bonus: No additional cost for base cam profile modification.

–Aesthetics

Free! \o/

ASPIRATION

-First case: making a turbo engine from a NA one, or the opposite (why should you do that?). You have to design a lot of new stuff and new calculations.

Cost: High (I’ll accept suggestion)

Bonus: Total free modification costs for all the remaining turbo related tabs.

-Second case: modify an existing the turbo setup without modifying the type of forced induction used.

–Setup

Without touching the turbocharger size you have to modify the exhaust header and some piping. Same intercooler.

Cost modification: Medium-low

–Options

Swapping between the two set of bearing shouldn’t affect the compressor or turbine design.

Cost: Very low

–Intercooler

Small modification in the intercooler size, placement and piping. Not a big fuzz to change it.

Cost modification: Low

–Compressor

Change the compressor size*.

Cost: Medium

–Turbine

Change the turbine size*.

Cost: Medium

–AR Ration

Modifying this affect the turbine housing size*.

Cost: Medium

–Max boost

Only the wastegate valve is going to be revised.

Cost: Very low

- I’m not sure if this items should be treated like the carburettors, as a component not designed inside the company. In that case should be less expansive?

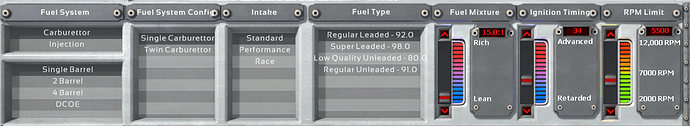

FUEL SYSTEM

–Fuel system

Carburettors are components that you purchase from a dedicated company (or not?) and they are easily replaceable, so you don’t have big developing cost switching between them. Moving from a carburettors system to an injection one it’s a total different story. Like changing the injection systems: all of them are totally different; it’ not to going be cheap.

Cost modification (between carburettors type): Low (Very low?)

Cost modification (between injection type): Medium

Bonus: No additional cost for intake modification (included in the carburettor redesign)

Malus: Additional cost if moving from carburettors to injection. Should be an extra extra-cost for move from and to Direct Injection.

–Fuel System Config

Change the intake manifold design and the throttle.

Cost modification: Medium-low

–Intake

Don’t be afraid, let’s tear down reliability and increase the service cost! You have just to unscrew this and that one…

Cost modification: Very low (or free?)

–Fuel Type

As long as you don’t change between leaded and unleaded fuel there are no problem. In the other case, the lack of tetraethyllead will damage the valves seal.

Cost modification: None / Very low (if moving from leaded to unleaded)

Bonus: Tiny discount for head type and valve quantity modification.

–Fuel Mixture

Free! \o/

–Ignition Timing

Free! \o/

–RPM Limit

Free! \o/

EXHAUST

–Headers

In the exhaust system the most expensive modification, but not so costly indeed. Some research must be done, if you are not going to choose for Race Tubular. In that case A LOT of research must be done.

Cost modification: Medium-low

Malus: Extra costs for race tubular.

–Exhausts

It shouldn’t take so much time to change it, but you have also to design a new path for the new exhaust pipe.

Cost modification: Low

Bonus: Discount in Exhaust diameter, catalytic converter, first and second muffler variation.

–Muffler bypass

Making it sporty?

Cost modification: Very low

Bonus: Discount on first and second muffler variation.

–Exhaust diameter

Take care of your back-pressure. It also change the flange on the muffler.

Cost modification: Low

Bonus: Small discount on first and second muffler variation.

–Catalytic Converter

Probably some development cost are required.

Cost modification: Low (in the rare case of removing an existing one, should be a free modification)

–First and second muffler

Cost modification: Very low (in case of muffler removal, it should be free)

Bonus: No additional cost for muffler bypass valve (included in the muffler redesign)

[size=120]SCENARIO[/size]

I’m in the campaign mode and I build a brand new engine for my new small hatchback in the 1978.

This is the “native” engine. A 1197cc 4 cylinder inline regular leaded fuel engine. Let’s see it naked.

(There is no aspiration tab, due the lack of turbo in this hypothetical scenario. It’s NA)

The engine cost $310.29 in material and $302.00 as production time (15.1 hours by 20$). The D/E/P cost me an additional YYYY (to be defined!).

The sales of the car aren’t good as expected. A lot of people want something sportier, due the sporty feeling of the good chassis it have under the skin. I don’t want to spend a lot of money building from scratch another engine so I will make a derivative engine from the Native with a very tight budget.

What we can do? I was expecting some “trouble” so I’ve designed the engine with “High” compression and lower setting for the ignition time.

If I’ll enrich the fuel mixture, remove the first baffled muffler, swapped the single barrel with the dual barrel, change the ignition timing and the intake I can squeeze 4kW more, a better economy and a lot of responsiveness. It’s louder too, but it’s the sport version of the hatchback. It’s also a bit quicker to produce due the lack of the first muffler. I think the power difference is not enough. I’ll spend a little bit on the camshaft and move the rev limiter to 6000.

Let’s see how should look in the game the modification (the bottom end will not show, due the lack of modify)

Results? HERE!

10kW more. Now it’s real sporty!

The engine cost $326.41 in material and $300.00 as production time (15 hours by 20$). The D/E/P cost me it’s way less and I can add a new version of the hatchback with very limited cost.

[size=120]DRAWBACKS[/size]

–Prestige

If a company launch a MY2000 Supermini with a revised engine that it used on their 1946 Small Sedan I think the customers will be disappointed. In order to balance the possibility to keep your old glorious post-war era engine still working in the future I think should be some prestige penalty in order to prevent the abuse of this derivative engine feature.

–Quality

Also a 1946 designed L4 block should probably have some old fashioned solution not suitable for the modern day and very costly to modify, so a new engine from scratch it’s a better solution. If I build a derivative engine in the 1990 of the '78 1197cc engine shown above, the components modified in the derivative engine are newer (higher quality) and the untouched parts should not gain a 1990 quality, but maybe some half-way… like a 1986 quality. (easy low cost revision after long engine use and huge feedback from your car retails/shops). I’m not sure that the game can handle this kind of dynamic but I think worth mention it.

All the aesthetic UI are poorly made in paint. It’s only a way to show the idea.

[size=120]CONCLUSIONS[/size]

Developers and community, please let me know what do you think, if could be useful, if should be revised and so on.

Thank you for reading such long post.

P.S.

ENGINE BLOCK MODIFICATION

Reading the history of the DFV engine (en.wikipedia.org/wiki/Cosworth_DFV ), I was wondering about the possibility to re-use inline configuration block in order to reduce the development cost of the V derivative engine (L3 → V6 / L4 → V8 / L5 → V10 / L6 → V12) forcing to keep the same bore and/or other components.

If Cosworth could do it, why the Znopresk or the Cossaks motors can’t do it?